Image quality and exposure time are two major parameters for non-destructive testing.

Indeed, reducing exposure time will result in faster workflow… However, reducing exposure time can also result in a lower quality image with a loss of details which influences the ability to detect small defects.

Image quality

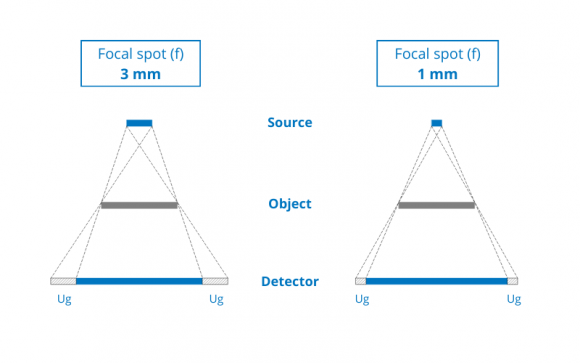

The geometrical un-sharpness (Ug) is a blurring of details in an X-ray image and is defined by 3 parameters:

- The size of the focal spot (f)

- The distance between the object and the detector (ODD)

- The distance between the object and the source (SOD)

Formula: Ug = f(ODD/SOD)

If one of those three parameters changes, the geometric un-sharpness will change as well.

A small focal spot (1 mm) minimizes un-sharpness and gives clearer images at the same distance.

Exposure time

We know that the focal spot size and the source to object distance are interconnected: if the focal spot size is reduced, the distance between the object and the detector can be reduced as well.

This means if the focal spot is 1.0 mm instead of 3.0 mm:

- The distance between the source and the detector can be reduced by up to one-third

- The dose rate of X-rays will increase by a factor up to nine

- The exposure time, as a result, will be reduced by up to nine times

Teledyne ICM’s small focal spot generator: the CP200DS & CP300DS

The small focal spot (1 mm) of the CP200DS & the CP300DS generator minimizes un-sharpness and gives clearer images, which makes it ideal for digital radiography (DR) when close X-ray shots are possible.

Our CP200DS & CP300DS are constant potential powerful generators (200 kV to 300 kV) with a metal-ceramic tube which turns them to be robust partners for a wide range of NDT applications. With its very light weight (15.9 Kg), the CP200DS has the best power-to-weight ratio in the world.

With a 100% duty cycle, the CP200DS & CP300DS have a built-in multiple X-Ray outputs carousel and, like the rest of the CPSeries product range, operate with the plug-and-play Powerbox control unit.

Do you want more information about our NDT solutions?

Contact us for a demo!