Chris Rawlinson is the Lead CUI Inspector at KAEFER. His responsibilities include sourcing and integrating effective technologies and processes for the reliable detection of CUI, ensuring KAEFER stay ahead in the field of nondestructive testing.

PROBLEM FACED BY THE CLIENT

What was your team’s process prior to using our product?

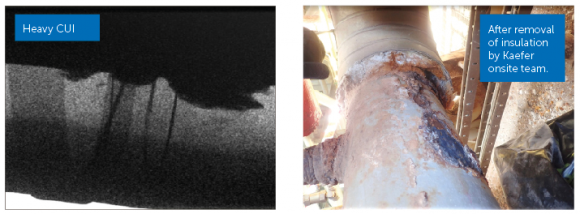

Prior to adopting RTR (Real-Time Radiography) for CUI inspections, our process relied heavily on physical insulation removal to visually inspect potential corrosion sites — an invasive, time consuming, and costly method.

What challenges/problems did you encounter? What were the major pain points of your process prior to using our product?

The major challenges included:

• High labor and material costs associated with insulation removal and reinstallation.

• Time inefficiencies.

• Limited access to some piping systems due to location or operational constraints.

Operator using our Go-Scan C-View to detect CUI © Kaefer Australia

DECISION PROCESS

What were you looking for in a solution?

We needed a fast, reliable, and truly non-destructive inspection method that could deliver accurate results without dismantling insulation.

How did you first hear about our products?

We discovered the product through targeted research into advanced inspection solutions and upcoming innovations in radiographic technology.

What features of our product was most appealing?

We were particularly drawn to:

• The high image quality and reliability.

• Ease of use in various field environments.

• The availability of uniquely adapted X-ray systems, especially those developed for the security sector, which translated well into industrial applications.

Images taken aboard FPSO in WA waters © Kaefer Australia

USE OF OUR PRODUCTS

How did you introduce our solution?

To build confidence with clients, we conducted both in-house and on-site trials. These demonstrations showcased the product’s capabilities and helped drive adoption.

How does our product help your company achieve its objectives?

The system has:

• Provided consistent and reliable inspection results.

• Enabled efficient service delivery.

• Demonstrated flexibility in adapting to our unique operational requirements.

Has this solution saved money and/or increased productivity?

Absolutely. The equipment has saved our clients significant time and costs by reducing the need for insulation removal and allowing for more flexible inspection planning.

How long have you been using our product?

We have used the C-Arm system (Go-Scan C-View, ed.) since 2019, and added the CP160B & Go-Scan 4335 digital panel in 2020.

What plans do you have to use our product in the future?

We aim to automate parts of the scanning process, allowing us to inspect larger diameters more quickly and further streamline workflows.

What is your advice for other teams or companies who are tackling problems like those you had before you purchased our product?

Invest in the right technology and ensure your team receives thorough training. The upfront effort pays off in long-term efficiency and reliability.

Operators installing our battery-operated portable X-ray generator, the CP160B, and our X-ray digital detector, the Go-Scan 4335, to perform an inspection. © Kaefer Australia

ABOUT KAEFER

KAEFER is a well-established provider of construction, maintenance and shutdown services. In 2018, KAEFER expanded its portfolio by introducing Corrosion Under Insulation (CUI) inspection services, aligning with industry demand for more proactive asset integrity solutions.

YOU WANT TO SHARE YOUR EXPERIENCE WITH OUR PRODUCTS?

CONTACT US:

Eva Libert — Marketing & Communication Manager

eva.libert@teledyne.com

+32 87 60 71 33